Nidaamka maaraynta wax soo saarka PMS Maamulka kaydinta duubka warqadda

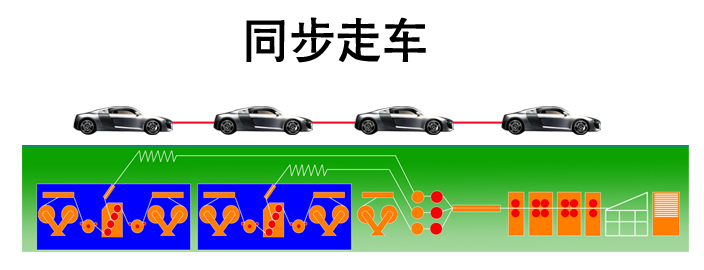

Xakamaynta isku xidhka

Isku-dubaridku waxay ka dhigan tahay in la xakameeyo xawaaraha wejiga keliya, waxay ku hayn kartaa xawaare la mid ah suunka shiraac ee muhiimka ah.Doorkeedu waa inay iska ilaaliso ururinta waraaqaha xad-dhaafka ah ama la jiido warqadda buundada.Sababtoo ah xawaaraha isbeddel degdeg ah, sahlan in la ruxo mashiinka, biibiile jiingado liidata, isku xirnaanta liidata iyo arrimo kale;maaraynta caafimaadku waxay ku salaysnaan doontaa sifooyinka matoorrada shakhsi ahaaneed ee xawaaraha kala duwan si ay u bixiyaan qalooca xakamaynta xawaaraha kala duwan, isku day inaad hoos u dhigto isbeddelka xawaaraha, oo aad hesho biibiile iyo koollo deggan oo lebbis ah.

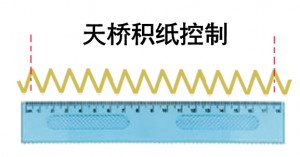

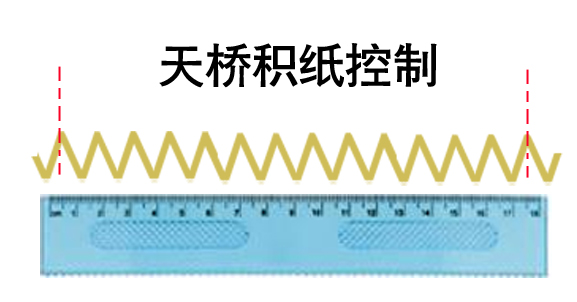

Xakamaynta Ururinta Waraaqaha Buundada Dusha Sare

Xakamaynta buundada sare, ma aha oo kaliya in laga fogaado jeexjeexyada waraaqaha iyo dhibaatooyinka ururinta waraaqaha, oo saameeya saxnaanta dhammaan isbeddelka warqadda qoyan iyo xaashida jeexjeexa buug-gacmeedka magdhowga tooska ah.Sababtu waa sahlan tahay, dhammaan khadka wax soo saarka, marka lagu daro buundada wabiga ah ee warqadda goobtu ma fududa in la qiyaaso, laakiin masaafada waxay ku dhowdahay xog go'an laga bilaabo rullaluistemadka ilaa suunka fuulitaanka, iyo sidoo kale ka tilmaanta xaashida nuugista buundada ilaa gooyaha NC.Dhab ahaantii waxay rabaan in la tiriyo, waa sida loo xisaabiyo mugga dhabta ah ee buundada warqadda, iyo sidoo kale qadarka magdhowga ogaanshaha tooska ah ee samaynta warqad xun oo uu jeexjeexay shaqaalaha buundada.

Baadhista iyo xakamaynta buundada, dabagalka iyo tignoolajiyada xakamaynta socodka;Dhinaca kale, la soco ururinta waraaqaha dhabta ah, dhanka kale, isticmaal qadarka quudinta suunka fuulista iyo buundada nuugista cadadka warqadda, si loo cabbiro xakamaynta socodka.Farqiga u dhexeeya labada cadad (qadarka jeexjeexa buundada) xakamaynta isku xidhka jawaab celinta si toos ah, si loo gaadho magdhow iyo ururinta buundada go'an.

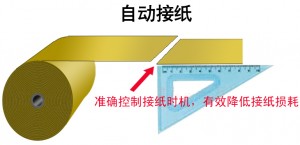

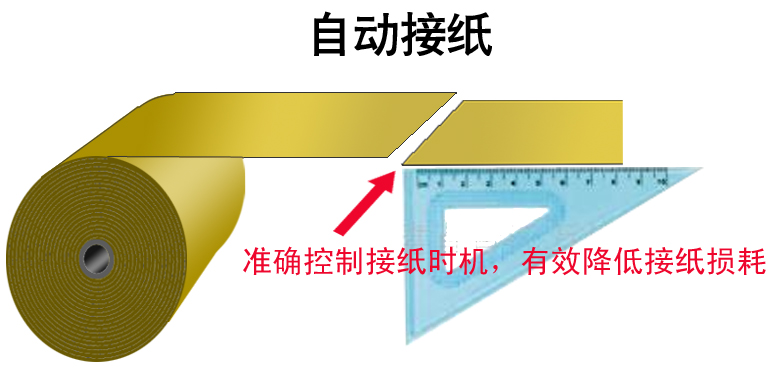

Xakamaynta otomatiga ah ee Splicer

Mashiinka kabidda tooska ah kuma xidhna kantaroolka oo keliya wakhtiga ku habboon, waxa kale oo ka mid ah ururinta buundada, synchronous, gaabi, ka hor inta aan la kala qaybin, iyo kontoroolka warqadda madaxa warqadda quudinta duudduuban ilaa soo kabashada iwm.

LCD-ga laba-geesoodka ah

Bandhig-waqtiga dhabta ah ee wax soo saarka hadda ee dhowr mitir, tirada mitir ee soo hartay;

Muujinta wakhtiga dhabta ah ee lambarka baabuurka hadda, celceliska tirada baabuurta;

Habaynta

Golaha kontoroolka weji keliya

Golaha kontoroolka wejiga laba jibaaran

Golaha xakamaynta dhamaadka qalalan

LCD-ga laba-geesoodka ah